Why Most Ground Handling Teams Waste 25% of Their Day Without Realizing It

On the ramp, every minute is a chain reaction.

A marshaller waves an aircraft in — but the pallet dolly isn’t where it should be. The loadmaster checks the manifest again, waiting for an updated weight sheet. The aerobridge operator stands by for clearance that’s still “on its way.”

It’s a rhythm that feels familiar.

It’s also one of the most expensive habits in aviation.

The Invisible Leak in Every Operation

Ground handling teams — from cargo units to ramp agents — operate in some of the most time-critical environments in the world. Yet, they lose up to 25% of their working hours to one silent problem: poor scheduling.

Not bad weather. Not broken equipment.

Just fragmented communication and outdated planning systems.

You see it in tiny delays that seem harmless:

- A missing load plan update

- A shift handover without full context

- A pallet dolly left two bays away

- A task assigned twice because two radios said different things

Individually, they’re small.

Together, they compound into hours of lost motion — across every shift, every team, every flight.

Where the Day Really Goes

Schedulers in ground operations still rely on a mix of spreadsheets, printed rosters, and WhatsApp groups to coordinate complex, real-time tasks.

By the time everyone’s updated, the plan has already changed. The cargo team moves ahead. The marshaller waits. The operator repositions.

No one is technically “idle,” yet the system as a whole slows down — like an aircraft taxiing in circles.

These micro-mistakes accumulate quietly. A five-minute delay here, ten there. Before anyone notices, an entire quarter of the workday has evaporated.

Precision Starts Before the Pushback

Aviation loves precision — down to the kilo, the second, the millimeter. But that precision rarely reaches the planning layer.

When shift assignments, task sequences, and equipment movements are managed in real-time — not on paper, not in post-shift reports — teams stop reacting and start anticipating.

That’s when the magic happens.

Turnarounds tighten.

Fatigue drops.

The chaos shrinks into flow.

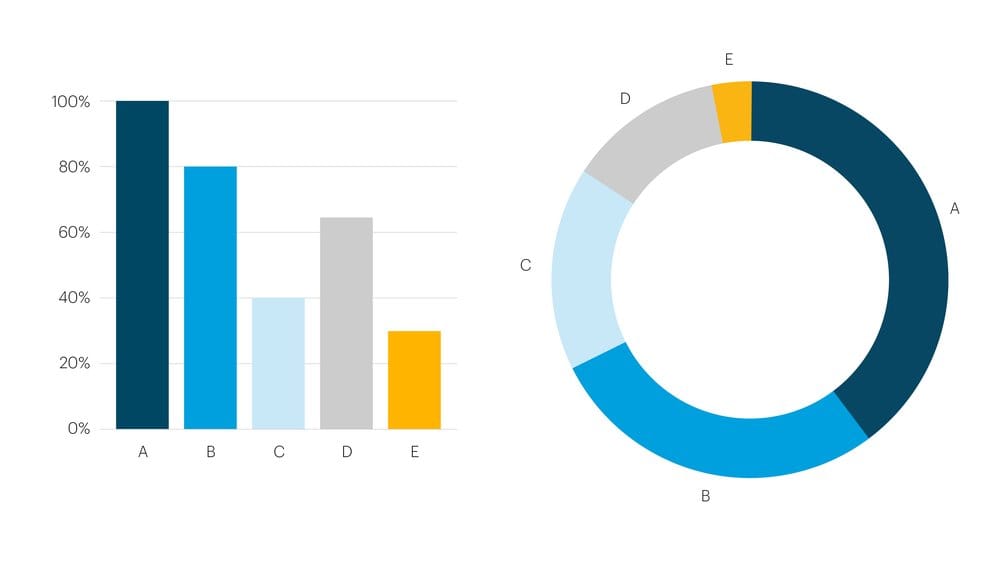

Scheduling isn’t just admin work. It’s the heartbeat of every ground handling operation — and most teams don’t realize how much time they’re losing until they see the data.

The Next Flight Starts Here

For marshallers, loadmasters, aerobridge operators, and cargo crews, efficiency isn’t about speed — it’s about sync.

Every piece of equipment, every shift, every movement depends on one thing: time discipline.

And that starts with scheduling that moves as fast as the ramp itself.

Because the real waste isn’t in delays — it’s in not seeing them coming.

"If you enjoyed this, a subscription would mean a lot and encourage me to keep writing. Thank you!"